Energy Services

Energy Production

Energy Services manages all of the utility generation and distribution systems for the University of Rochester.

Electricity

Energy Services operates and maintains UR's internal medium voltage (4,160V - 11,500V) electrical grid. This includes substation #710 on Kendrick Road where electricity is delivered from RG&E to UR, all the high voltage circuits and switchgear between the substation and the campus buildings and the primary transformers for each building. Energy Services owns and operates two co-generating steam turbine generators, which can produce up to 25MW of electricity and provide heat to the University hot water system. These generators produce about one third of River Campus and Medical Center electricity, with the remaining two thirds purchased from RG&E.Chilled Water

Energy Services operates and maintains the UR chilled water generation and distributions system. Up to 12,000 tons of chilled water is produced in five electric driven chillers at the Mid Campus Chiller Plant (MCCP) and up to 22,000 tons of chilled water is produced by four steam driven chillers at the Central Utilities Plant (CUP). Energy Services also maintains the underground chilled water distribution piping from the CUP and MCCP to campus buildings and the chilled water connection point inside each building.Steam

Five steam boilers inside the CUP burn natural gas to produce steam at 900 PSI or 165 PSI. We maintain all the steam distribution and condensate piping that travels from the CUP to many River Campus buildings and most Medical Center buildings up to and including the pressure reducing stations or steam to hot water heat exchangers in the buildings.Hot Water

(AKA Co-Gen hot water): Heating Hot Water produced at approximately 185°F in the summer and up to 225°F in winter is distributed primarily underground to buildings on River Campus, Medical Center and Mid Campus. Once inside the building it is transferred to the building's HVAC system by an Energy Transfer Station (ETS). Energy Services is responsible for operating and maintaining the generation of the hot water, all of the distribution piping and the ETS. The majority of the energy to produce the hot water comes by reclaimed heat from the co-generation process.Co-Generation

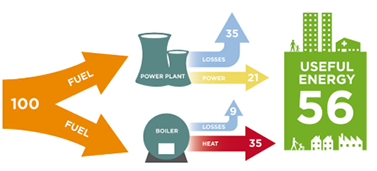

This is not a stand-alone utility but a process that integrates multiple utilities. The co-generation process of producing two utilities (electric and hot water) with one source (steam) results in a system that is much more efficient then generating electricity and hot water separately. Boilers burn natural gas to produce steam, which is used to drive a turbine to produce electricity. The "waste" product of this process is vacuum pressure steam (below atmospheric pressure), which still carries a lot of thermal energy. The latent thermal energy from the vacuum pressure steam is transferred to hot water, which allows the steam to condense and be recovered for reuse in the boiler. Campus buildings are heated with the hot water. Electrical generation is inherently inefficient. Generating electricity by itself results at best in efficiencies in the 30-40% range. When you combine the process of electrical generation with hot water generation, much of the wasted heat from the electrical generation is recovered as usable heat for the hot water, resulting in much higher combined efficiency.

Natural Gas

Energy Services maintains and operates a University owned natural gas distribution system on campus. The Central Utility Plant consumes the majority of the campus's natural gas producing steam, but a few buildings use natural gas for cooking or research.Domestic Water

Also known as potable water is used for drinking, cooking, bathing, laundry, etc. This is clean water that is provided by the City of Rochester to the Campus. Domestic water is used in every building on campus. Energy Services maintains all of the distribution piping between the City of Rochester and each building.Fire Water

Supplied by domestic water, fire water supplies fire suppression sprinklers with water to extinguish fires in the event of an emergency. Because of its critical nature, fire water often has its own dedicated water mains feeding a building. Energy Services maintains all of the fire water mains between the City of Rochester and the backflow preventer in the building.Storm Water

There are a system of storm water drainage pipes, tunnels and cisterns that collect rainwater and give it a path to flow safely off the campus. Most of this infrastructure is underground and invisible to the naked eye. Energy Services maintains this entire infrastructure on campus.Sanitary Sewer

The sanitary sewer collects all of the sanitary waste from each building and transfers it to the Monroe County department of Pure Waters where the sewage is treated and cleaned before returning it back to the environment. On campus, sewage is comprised of collecting the contaminated water from sinks, showers, toilets, etc. Energy Services maintains all of the Sanitary Sewer system between each building and Monroe County.Meters

Energy Services maintains all of the 800+ meters that provide utility and energy usage data for each building on campus. We also manage the bills and data from hundreds of external utility owned meters on and off campus. Data from University owned meters is collected in our OSIsoft PI system and is available to University faculty staff and students through our Energy Management information System. Meter data is used to identify opportunities for energy conservation projects inside buildings, validate savings from energy conservation measures, verify bills from external utility providers, and allocate energy costs inside the University. The EMIS collects data from approximately 380 electric meters, 60 natural gas and fuel oil meters, 150 water meters, 140 steam meters, 140 hot water meters and 70 chilled water meters.

Contacts

John Welch

- Assistant Director of Production

- 275-8931

- jwelch24@facilities.rochester.edu

Brian Wilson

- Manager, Operations

- 794-2240

- bwilson@facilities.rochester.edu

Jeff Jones

- Manager, Instrumentation and Controls

- 273-4824

- jjones@facilities.rochester.edu

John Stephany

- Manager, Maintenance

- 474-2017

- jstephany@facilities.rochester.edu

Nik Terpak

- Assistant Director, Electrical Systems

- 273-4880

- nterpak@facilities.rochester.edu

Mike Rink

- Sr Electrical Project Manager

- 275-4810

- jrink@facilities.rochester.edu

Jill Chudyk

- Department Coordinator

- 275-3672

- jchudyk@facilities.rochester.edu